MJS Packaging’s most recent webinar “A Guide to Labels: Perfecting Your Product’s Billboard,” covered packaging label capabilities from A to Z. It was exciting to host this educational session with Repacorp’s label experts Rochelle Heinl, Vice President and Nick Heinl, VP of Shrink Sleeve Labeling and our experienced MJS Packaging Account Executive, Jared Van Hees. Read more to learn what was shared.

LABELING BASICS

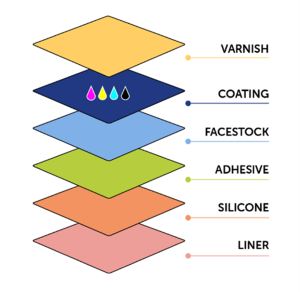

If you are new to the intricacies of labels, get ready to be wowed. There are so many layers involved in a structurally sound label. Labels first sit on liners (paper or synthetic based) and these liners are coated with silicone so that the adhesive-backed label releases off the liner. Next, the facestock features adhesive on the bottom and print-receptive coating on top. If a last layer is needed, it could consist of a liquid varnish or synthetic tape laminate. Coatings are gloss, matte, satin, soft touch or textured.

Two types of adhesives are used: a rubber base and an acrylic. Rubber-base adhesives are great for applications with textures, dust or products like corrugate boxes, but they are not good for high-heat or low-temperature conditions. Acrylic adhesives are more all-purpose and good for all-temperature jobs. The facestock is the layer you visibly see. There are thousands of materials to choose from, including papers, plastics, foils and dissolvable materials. The most common labels you will encounter are pressure-sensitive. Since they are fully adhesive-backed, these labels can be applied by hand or machine.

PRINTING TYPES

Two common production methods are traditional flexographic printing or digital printing. Traditional flexographic printing involves making and setting print plates, ink pans and cutting dies, resulting in more setup, waste and cleanup. This method is typically for larger jobs (over 10,000 ft. of material). Digital print is less costly for smaller quantities that are custom printed. A computer directly prints the material with digital print, resulting in very little waste, setup or cleanup. Additionally, laser die cutters save money and time on the digital print end compared to engraved tooling in the traditional printing process.

VARIABLE PRINT

Variable printing can be done on traditional or digital presses. Variable printing involves unique label aspects printed on each individual product. Variable printing allows for barcoding, varying packaging designs and personalized messaging. This is something to keep in mind for creating special runs such as custom holiday packaging.

RFID LABELS

Have you considered improving your product traceability? Walmart is requiring a number of supplier categories to label their products with Radio Frequency Identification Device (RFID). RFID labels have different capabilities than a simple barcode. Both allow you to track products, but RFID tags provide more information including finite product detail, as well as time, date and stamping. RFID data can even be updated after they are attached to the product. These tags can be read within a range of a few centimeters to over 20 meters. RFID labels are great for inventory management, asset tracking, loss control and improved supply chain visibility.

SHRINK SLEEVES

Shrink sleeves offer tamper-evident sealing, water, fade and scratch-resistance and combo packing capabilities. The sleeve slips over the container, and it shrinks down to any shape or size container once heat is applied. This gives you a 360 canvas for graphics.

A roll of sleeves can be provided for automatic application or they can be individually cut and stacked for manual application. Shrink sleeves can even seal up over the cap and tear down with perforation for tamper evidence. Decoration finish options include varnishes, metallic inks, textured coatings and foils. Film materials consist of:

- Polyvinyl Chloride (PVC)

- Most commonly used material and easiest to control

- Polypropylene Terephthalate Glycol (PETG)

- Top-notch scuff resistance, recyclable

- Oriented Polystyrene (OPS)

- Most consistent finish, used for squeezable containers

INCREASING PRODUCT SECURITY

You can also combat counterfeiting with labels. Anti-duplication inks can take different shapes and forms. Coin reactive coatings consist of a varnish coated with security ink, which you can remove with a coin. You can also choose ink only visible in infrared light, iridescent inks that change when viewed from different angles or pen-reactive invisible inks. Thermochromic inks change color when exposed to heat or cold. Photochromic inks shift color when exposed to UV light versus UV Fluorescent print that becomes visible when exposed to UV light.

CASE STUDIES / APPLICATIONS

Now that you know more about label basics, varieties and capabilities learn more about what we have done for our customers.

Jared and our Repacorp partners eliminated air bubbles trapped under the label for Thetford’s Campa-Fresh product. We sourced a special substrate and eliminated the bubbles to keep this item looking professional.

Killer Food Plots launched a new spray bottle featuring a continuous spray trigger. A shrink sleeve was the right application to complement this distinct bottle shape and design. A shrink band was added to keep the actuator inactive during shipping. MJS Packaging was proud to develop this National Association of Container Distributors (NACD) award-winning package.

We stepped in to help The Brinery utilize a much stronger label for their Storm Cloud Zapper Sauerkraut. We procured a pressure-sensitive label that can withstand colder temperatures. Now, they don’t have to worry about any label peeling during refrigeration.

WE KNOW LABELS & PACKAGING

Labels provide a great opportunity to differentiate your product and give it a custom look. It’s far more cost-efficient to customize with a label than to produce a custom container. Our experts work with you to create the best label for your product. Let’s talk about your product goals and specifics and determine everything you need in a label: size, material, printing location, quantity, application method, perforation needs, finish preference and more. MJS Packaging provides a wealth of experience in packaging for a variety of industries and we are more than equipped to create a label that meets your needs.

Missed the webinar? You can still watch it on our webinar page. To learn more or start a label project with us, contact us today.