Plastic trigger sprayers were first used as spray pumps to allow for various commercial and domestic liquid products to be distributed to households through retail outlets. Trigger sprayers are usually made from a variety of plastics and can be used for water-based and chemical-based liquids. A trigger sprayer is attached to a compatible spray bottle that allows the contents to be dispersed when the consumer squeezes the pump handle on the trigger.

The most common use for trigger sprayers is with household cleaning products such as disinfectants, floor and surface cleaners. This has especially been the case in the past year due to the COVID-19 pandemic. There was a huge increase in demand in 2020 for trigger sprayers for disinfectants and cleaning products.

The Benefits of Trigger Sprayers

One of the major benefits of using trigger sprayers is the ability to control the amount of the content that is dispensed. The nozzle can be adjusted to create a fine spray or jet stream for dispensing liquids. Another benefit is trigger sprayers come in a variety of colors and sizes. This makes it easier for the consumer to easily identify different products.

Things to Consider with Trigger Sprayers

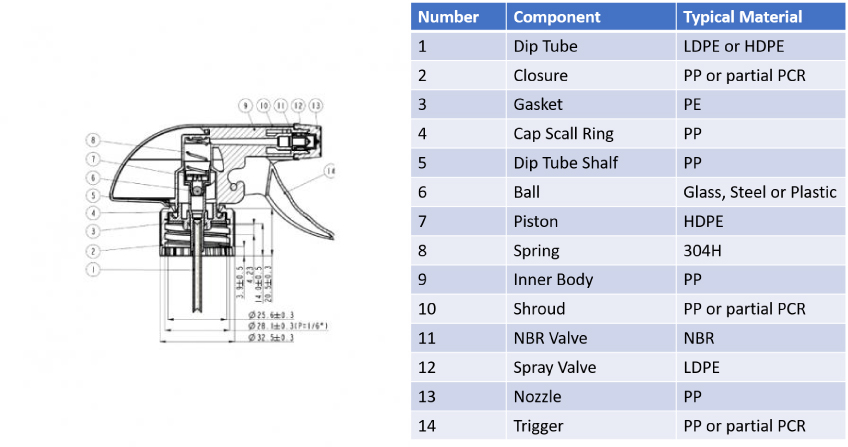

As you can see from the diagram, the overall trigger sprayer system consists of 14 components. Many of these components can be made from a variety of materials depending on your product’s needs. It is important to review each of these components to make sure you select the best system for your product. Read on below for further details into some things to consider when selecting a trigger sprayer.

Your Product & Output

The first consideration is to identify what type of product you will be dispensing with the trigger sprayer. Certain ingredients are only compatible with specific materials for components such as the ball, dip tube, etc. Based on your product, you will also need to determine what output you need from the sprayer. The output typically ranges from 0.7cc to 1.6cc.

Understanding the Filling Process

You will need to be familiar with the filling process used for your product to make the best choices. Whether you are using a manual or automatic filling line, there are different specifications you will need to follow.

Considering the Dip Tube

The dip tube is an important component of the trigger sprayer that should not be overlooked. Depending on the bottle size you’re using, you’ll need to tailor the length of the dip tube. In addition, you will also need to consider how rigid you need the dip tube to be and select a material that matches your needs.

What Nozzle To Use?

The nozzle is a big feature when it comes to the consumer experience. This gives the consumer control on how the product will dispense. There are several options with the nozzle. You can give the consumer the option of a nozzle that allows your product to spray, stream, mist or have it in an off position, or choose a nozzle that simply twists open.

Sustainable Materials

Trigger sprayers are made from a variety of materials. If choosing a more sustainable trigger sprayer is important to you, then consider the use of PCR for a portion of the material for several components such as the shroud, closure and trigger.

What Neck Finish To Use?

You will need to choose a neck finish that is compatible with your bottle and your product. A typical cleaning product often uses a bottle with a 28-400 or 28-410 finish. If you have a harsher chemical such as a lawn pesticide, you may look to a ratchet finish to keep the cap and sprayer from loosening from the bottle.

There is also the option of a bayonet/snap-on trigger sprayer. These can only be used with very specific bottles and are very difficult to remove, thus making them a good option for products that should be specifically kept out of the hands of children.

How Can MJS Packaging Help?

If your company is starting to utilize trigger sprayers and bottles for your products or needs a refresher on the various options, MJS Packaging can help. We have a strong understanding of all that need to be considered when using trigger systems.

Contact MJS Packaging today or talk with one of our knowledgeable packaging solutions specialists by calling (800) 915-2262.