In today’s ever-evolving world, one packaging solution stands out as both innovative and sustainable – flexible pouches. These versatile packages have gained popularity in recent years, and in this blog post, we will explore what they are made of, their various types, and why they are such an excellent choice for a wide range of products.

The Popularity of Flexible Packaging

Flexible packaging, in the form of pouches, has risen to prominence due to the growing global emphasis on sustainability. These pouches are renowned for their minimal environmental impact, making them a preferred choice for eco-conscious manufacturers and consumers.

Flexible pouches offer sustainability advantages due to their reduced material usage compared to traditional packaging options. Constructed using fewer resources, the process helps to conserve raw materials and reduce carbon emissions. Furthermore, their lightweight design minimizes the carbon footprint during distribution.

These claims are backed by the Flexible Packaging Association (FPA), which provides this list of facts from their latest findings:

- Producing a flexible food service pouch requires 75% less energy and generates just 1/10 of CO2 emissions during production than a metal can for the equivalent amount of product.

- 1.5 pounds of flexible packaging will package the same amount of beverage or liquid foods as 50 pounds of glass.

- To transport packaging for an equal amount of product, it takes more than 26 truckloads of empty glass jars versus one truckload of empty flexible pouches.

Additionally, flexible pouches are highly adaptable, making them suitable for various product types. Their ergonomic design not only reduces packaging waste but also enhances the consumer’s experience by being easy to open, store, and reseal, thus extending the product’s shelf life. These factors combine to make flexible pouches an attractive choice for brands looking to cater to environmentally conscious consumers without compromising functionality.

Layers in Flexible Packaging Pouches

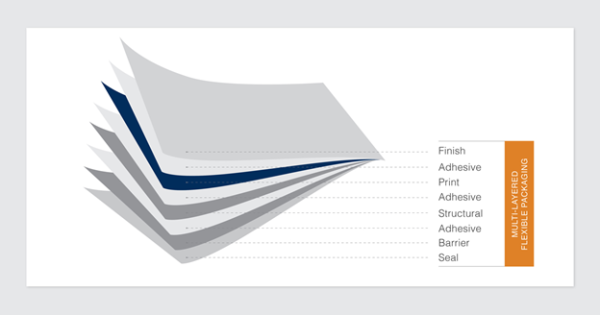

Flexible pouches are more than just a single layer of material; they are a composite of carefully selected layers that work harmoniously to protect and present your products effectively. Let’s take a closer look at these layers to understand their roles:

- Sealant Layer: The innermost layer safeguards against leakage and assists in setup of functional package aspects like fitments and closure applications.

- Barrier Layer: The barrier layer is crucial for protecting the product, preventing tears, and preserving shelf life. Materials like aluminum foil and other metalized films provide excellent barrier properties, blocking out light or inhibiting oxygen, moisture, and odor from entering or exiting the package.

- Print Layer: The print layer is where the pouch gets its vibrant graphics and branding. High-quality printing enhances the visual appeal of the package and communicates essential information to consumers, such as product details and instructions.

- Structural Layer: Structure layers offer fortitude and puncture protection for your pouch.

- Finish Layer: The finish layer serves both aesthetic and functional purposes. A matte, glossy, or soft-touch finish enhances the tactile and visual appeal of the pouch while also protecting the design of the print layer.

- Adhesive: Adhesive can be used to combine layers in a multi-material flexible package. Several lamination methods can be used, such as solventless, solvent based, or water based, depending on the unique needs of the package.

Image Source: Nobelus University

Materials Used in Flexible Pouch Films

The choice of materials for the various layers of flexible pouches depends on the specific requirements of the product and the desired outcome. Here are some common materials used in flexible pouch films and their benefits:

- PET (Polyethylene Terephthalate): PET is often used or incorporated into the barrier layer of flexible packaging. Polyester is useful for transparent packaging solutions (like view windows) and metalized films.

- Aluminum Foil: Aluminum foil is an exceptional choice for the barrier layer. It offers high resistance to moisture and oxygen entering the package and ensures the product’s freshness and longevity by retaining odors and flavors.

- PE (Polyethylene): PE is a good option for the sealant layer and can also be used in the barrier layer when combined with other films.

- BOPP (Biaxially-Oriented Polypropylene): BOPP films are unique in that they provide a moisture barrier and serve as an excellent printable film for high quality graphics with great clarity.

- Paper: For a more natural and eco-friendly look, some flexible pouches are made with paper. Paper can provide rustic charm, protection, and recyclability.

Sustainable Options: To meet the growing demand for eco-friendly packaging, sustainable materials like recyclable plastics, bio-based films, and compostable materials are increasingly being incorporated into flexible pouch designs. These options reduce the environmental footprint of the packaging while maintaining performance and functionality.

Common Types of Pouches and Their Benefits

Flexible pouches come in various designs to cater to different products and consumer preferences. Here are some common types and their associated benefits:

- Stand-Up Pouches: These pouches have a design that allows them to stand upright on store shelves. They are excellent for products like snacks, coffee, and pet food, offering convenience and visibility. You can choose from a variety of stand-up styles with different bases from gusseted to flat bottom.

- Lay Flat Pouches: Lay flat pouches are versatile and ideal for products that need to lie flat, such as frozen food and spices, and for products in personal care, pharmaceutical, and home and garden markets. The lay flat design is easy to store and stack.

Besides the layers and pouch types, several other elements can be incorporated into flexible pouches to enhance functionality and convenience. These include:

- Closure Types: In addition to zippers, pouches can feature options like sliders, press-to-close seals, or even resealable tape for easy access and resealing.

- Degassing Valve: Used for coffee and other products that emit gas, a degassing valve allows gases to escape without compromising the pouch’s integrity, ensuring freshness. It allows carbon dioxide to escape but doesn’t allow oxygen in.

- Side Seals: Side seal pouches often take up less space, making them optimized for transportation, storage, and point-of-purchase or aisle displays with hang hole. Three-sided sealed pouches are cost-effective and great for grab-and-go consumer products.

- Zipper Pouches: Pouches equipped with resealable zippers are perfect for products that consumers want to use gradually, like snacks and pet treats. The zipper ensures freshness is maintained after each use.

- Spouted Pouches: These pouches come with a spout for controlled pouring, making them ideal for liquids such as sauces, beverages, and baby food. The spout design minimizes mess and waste.

- Add-Ons: Pouches can be customized with features such as handles, tear-notches, custom shapes, child resistant features, and transparent windows to showcase the product inside.

An assortment of pouches can be ordered from MJS Packaging that fit your unique needs, including preformed, rollstock or custom. Preformed pouches will save you time, as they are already shaped and formed, ready for you to fill and close. Rollstock consists of a roll of unformed pouches. Forming, filling, and sealing the rollstock pouches on your own can allow for cost savings if you already have your own in-house machinery.

Start A Project With Us

Flexible pouches have become a staple in the world of packaging due to their sustainability advantages and versatility. As consumer preferences shift toward more eco-friendly choices, flexible pouches will continue to stand out as a leading choice.

At MJS Packaging, we pride ourselves on providing consultative excellence in flexible pouch packaging solutions for various industries. Whether you need preformed pouches, rollstock, or a customized flexible packaging solution, we have the expertise to meet your unique needs. Contact us today, and trust MJS Packaging to deliver pouches that not only meet but exceed your expectations, enhancing your brand’s presence in the market. Start a Project with us today!