When you know the fundamentals about closures and how to heat seal liners can help optimize the way your product is capped, the next step we recommend is getting familiar with additional possibilities and liner options for even more of an advantage. With that in mind, here are some cool ways to get more out of your heat seal liners.

Know the Basics About Heat Seal Liners

Heat seal liner components: Heat seal liners can be one-piece or two-piece, depending on the type of product and how the product is intended to be used. A one-piece liner consists of a foam-backed or paper-backed foil laminate. With a two-piece liner, there are two additional layers consisting of wax and pulp board.

The process of attaching heat seal liners: When using a cap with a heat seal liner, the product is filled into the bottle or jar and the cap is put into place. The filled container is then sent through a heat tunnel, causing the liner inside the cap to adhere to the bottle or jar. This process can cause restrictions on what products can safely and effectively utilize heat seal liners. With a one-piece liner, the entire liner will be removed from the cap after the sealing process. The heating process melts the wax in a two-piece liner. The wax is then absorbed into the pulpboard, releasing it from the foil liner. The pulp board layer remains inside the cap for improved resealing after the foil liner has been removed.

Choosing a one-piece liner or a two-piece liner: A one-piece liner would be used for a single-use product or dry product, while a two-piece liner would be used if there is liquid inside or if the package will be resealed. The two-piece liner makes it possible for a package to function as a resealable, multi-serving container.

Additional printing space: On the top side of a product’s heat seal liners, you get an additional surface that can be printed or left plain. Printed liners generally carry messages like “Sealed For Your Protection” or “Sealed For Freshness”, but there is also room to get creative here.

Choosing a thickness: Heat seal liners can be any variety of thicknesses. The cap will have to be manufactured to function properly, however, so some limitations may apply.

Liners can be cut in a variety of ways: For a full list of cuts for heat seal liners, see the information below.

Options for Varying Liner Cuts

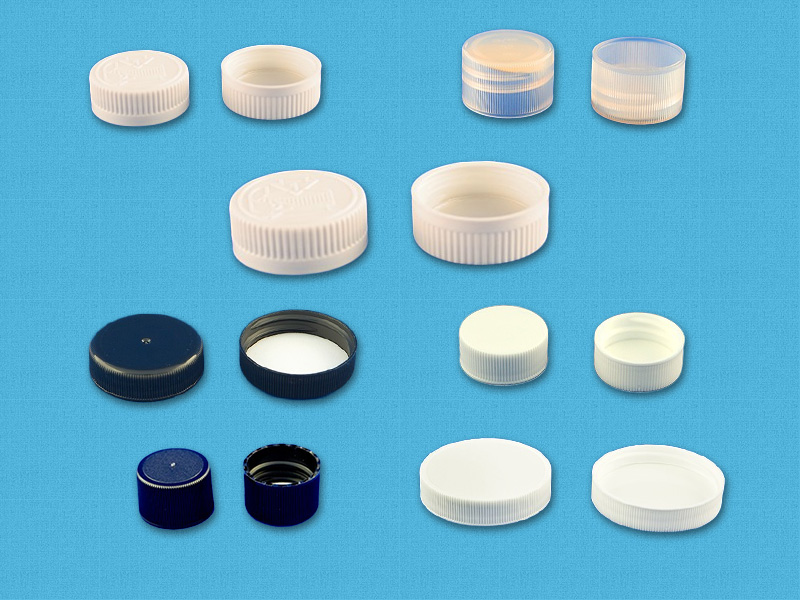

Depending on your preference and those of your consumers, you have many options for heat seal liners. Here is how it all breaks down.

Disc Cut Heat Seal Liners: Disc cut or round cut liners are the same sizes as the container (no tabs to grab).

Tri-Tab Heat Seal Liners: Tri-tab liners have three tabs cut into them for the consumer to grab to remove the liner.

Lift ‘n Peel Heat Seal Liners: Lift ‘n peel liners have a half-moon on top to easily remove the liner (this is a one-piece liner).

Top Tab Heat Seal Liners: Top tab liners look very similar to lift ‘n peel liners, but it is a two-piece liner.

Folded Back Tab Heat Seal Liners: Folded back tab liners utilize a single tab that folds back.

Folded Down Tab Heat Seal Liners: Folded down tab liners utilize a single tab that folds down.

Sorting Through the Many Options for Liners

Admittedly, closures, liners, and other cap components can be confusing. And, as these options demonstrate, there can be much more to them than expected. For a full introduction to your liner options and everything else, you may need to increase clarity and cut down on confusion, read more from our blog or contact us here.