MJS Packaging’s recent webinar, “Exploring Tube Packaging: Discover What You May Be Missing,” featured seasoned Account Executives James Daniell and Greg Clarke discussing the rising popularity of tube packaging solutions. We look at some of the main points covered in the webinar, including features that make tubes a desirable packaging option, consumer trends and how you can incorporate tube packaging for your business.

Tube Packaging – A Top Consumer Option

Tube packaging has become highly popular in healthcare, cosmetics and food industries. Personal care remains the top market for tube packaging, including household items such as toothpaste, shampoo, hair cream and sunscreen.

Market research shows the global squeeze tube market priced at $10.47 billion, with numbers expected to grow at a rate of 6.01% CAGR between 2022 to 2030. Additionally, industry statistics show that U.S. shoppers will spend an estimated $24.5 billion on beauty and cosmetic products online in 2023.

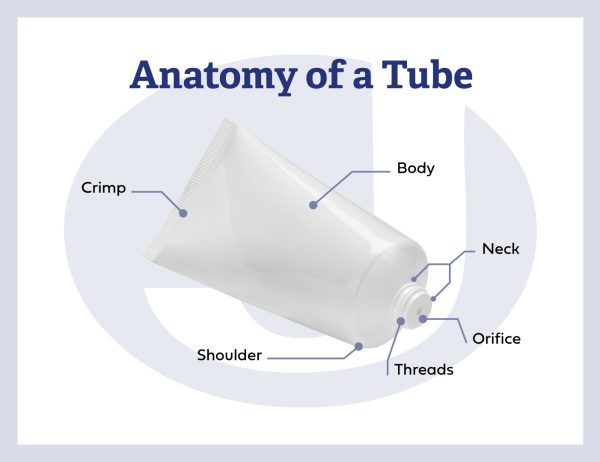

The Tube Packaging Anatomy

Standard tube packaging features the following parts:

- Orifice – The opening where the product contained within the tube gets dispensed.

- Neck – The narrow portion of the tube connected to the cap. The part features threads for securing the tube cap.

- Shoulder – The area between the neck and body of the tube.

- Body – The main portion of the tube that contains the product and provides the space for graphic printing and labeling.

- Crimp – A tube’s folded and sealed end that prevents the product from leaking from the packaging.

Tube Packaging Customizations

You can customize tube packaging formats, closures and body material to help your business design the perfect packaging aligned with your branding and customer needs.

Body Designs

Tube packaging bodies are available in two categories: monolayer and multilayer designs. Monolayer designs involve the use of a single plastic, such as polypropylene (PP), high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Tube manufacturers may also create products with aluminum.

Multilayer tube designs are usually composed of a combination of HDPE and aluminum or ethylene vinyl alcohol (EVOH) and other plastics laminated together. A multilayer design includes barrier layers that provide products with added protection against environmental contaminants. For example, manufacturers may use aluminum as a barrier layer with HDPE multilayer tubes to prevent leaching and corrosion of the packaging.

Formats and Closures

You can also customize the format and closure of your tube packaging according to product application. James shared several popular configurations of tube designs, such as dual chamber designs for separating products that are used together but shouldn’t be mixed, such as cosmetic formulations (e.g., skincare cleanser and moisturizer). Similarly, you can select a closure design according to the product type, such as a narrow tip design suitable for squeezing small quantities of a product or applicator closures that spread substances across a large surface area.

Printing Options

Tube packaging offers several printing options with varying costs, graphic quality and minimum order quantities (MOQs). You can choose up to six graphics for each tube packaging design.

Digital printing methods cater to low quantities or variation, while offset methods work best for low-cost production, although at the expense of graphic quality. Hot stamping and silk screen printing create attention-grabbing appearances, such as metallic accents.

In-mold label (IML) printing options have become increasingly popular for their premium and fully integrated aesthetic. Greg lauds IML as the “Cadillac of tube packaging printing” with its optimized graphics, retained shape and fully recyclable PP design. MJS Packaging recommended the IML method in collaboration with 3M, resulting in superior barrier qualities and high-impact graphics.

The Favored Packaging Solution

Many consumers have opted for tube packaging solutions for their compact convenience, mess-free dispensing, and waste reduction (less scrapping than other packaging options). Consumers also prefer tube packaging for its conveniently measured servings and recyclable design, making it a perfect solution from an environmental and eCommerce logistics standpoint. In addition to their convenient capacities, tubes have a lightweight design that reduces the transportation price, making them cost-effective for eCommerce sales across long distances. The high-quality graphic display of tube packaging also offers eCommerce customers a clear understanding of products when viewing them on their screens. Tubes have rightly earned their status as a favored packaging option due to their excellent barrier properties, high ease of use, and manufacturing and shipping simplicity compared to other containers.

Finalizing Your First Steps in Tube Packaging

While tube packaging can prove cost-efficient for your business, it is essential to consider some considerations for a smooth experience. For instance, your business needs specialized equipment for the filling process (since it functions through a bottom-up approach, the opposite of other packaging methods). However, the cost of entry for the required equipment comes at an affordable price, and ultimately, the pros of tube packaging far outweigh its cons.

MJS Packaging – Your Trusted Expert in Tube Packaging Needs

MJS Packaging offers generations of experience helping companies to the most suitable packaging options. Our experts provide detailed guidance in selecting the most effective tube packaging solutions based on the dimensions, materials and features your business needs. Plus, we can help connect you with trusted tube packaging fillers with the most cost-effective arrangement.

If you still need to catch the webinar, watch the recording of it on our webinar page. To learn more or start a project using tube packaging, contact us today!